Lojer 100 years

Part 1:

Niilo Ranni founded Vammalan Konepaja in 1919. Prior to this Ranni worked for a local engineer named Lindström in Vammala. Ranni developed production methods for Lindström, such as for the manufacture of weights for scales. Ranni was a metal worker who had no formal qualifications, but started his own workshop nonetheless. His workshop reflected some of the needs in post-war Finland: many skills and services were needed, and Vammalan Konepaja did its best to fulfil them. The company grew, and only three years later in 1922 Ranni decided to buy his own premises, complete with residence, in the centre of Vammala.

Part 2:

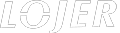

In 1930's Vammalan Konepaja manufactured kick sleds, steelyards, lifting weights and shot puts among others. In 1934, a contract was made between the Finnish Athletics Federation and Vammalan Konepaja, under which Vammalan Konepaja started to make the shot puts used by both men and women in competitions. The contract was signed on behalf of Vammalan Konepaja by entrepreneur Niilo Ranni; signing on behalf of the Athletics Federation was its then chairman, Urho Kekkonen, who would go on to become Finland’s eighth president.

Part 3:

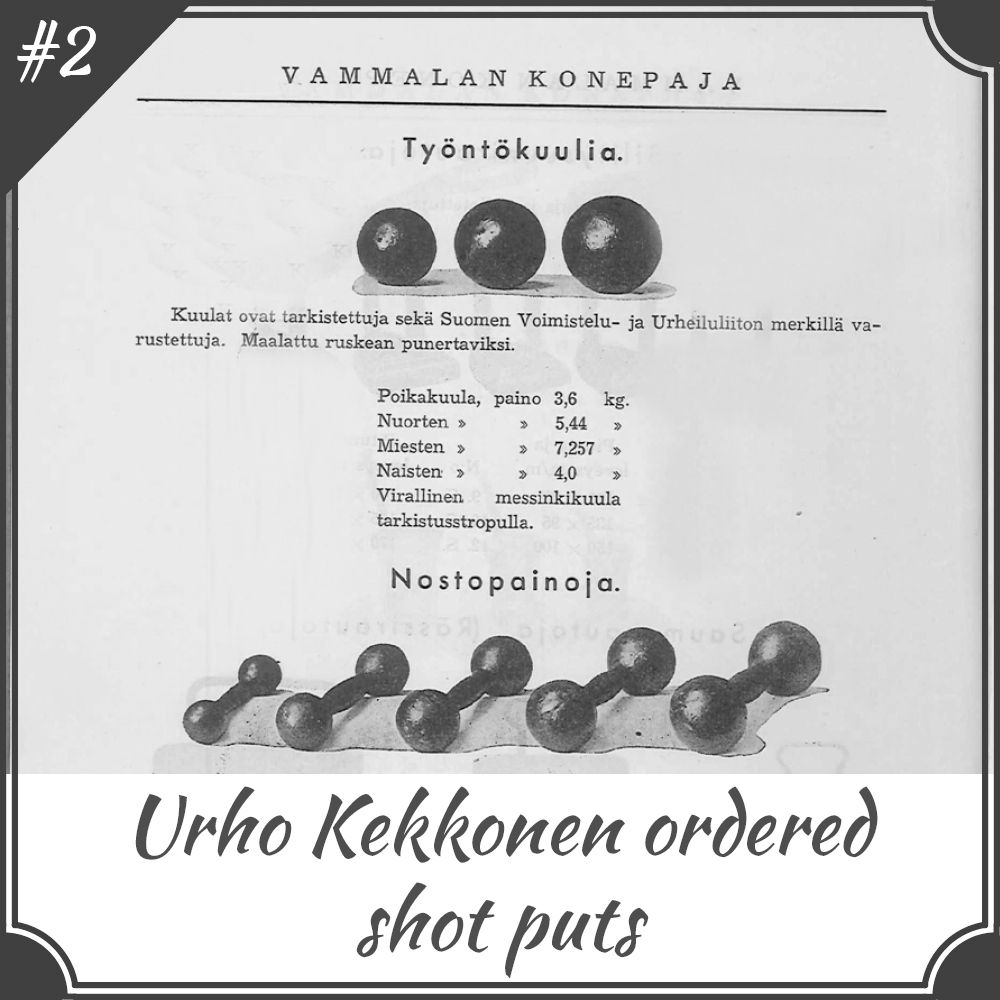

In the late 1930s and the 1940s the Winter War and the Continuation War also affected Vammalan Konepaja’s activities. The company had been trading for twenty years when, on the eve of the Winter War, the armoury was moved from the capital to Vammala. Weapons workshop 1 took up residence in Vammalan Konepaja’s premises on 3.11.1939. At first, the armoury’s role was to prepare M91 rifles and to fix M09 machine guns. Later, the armoury worked with Vammalan Konepaja to make parts for machine gun locks and pistols. It has been estimated that around half the artillery shells fired during the last wars were made in the Vammala armoury. After the wars Konepaja took part in war reparations by manufacturing a variety of machine parts. It was also around this time, in 1943, that the company became a limited company.

Part 4:

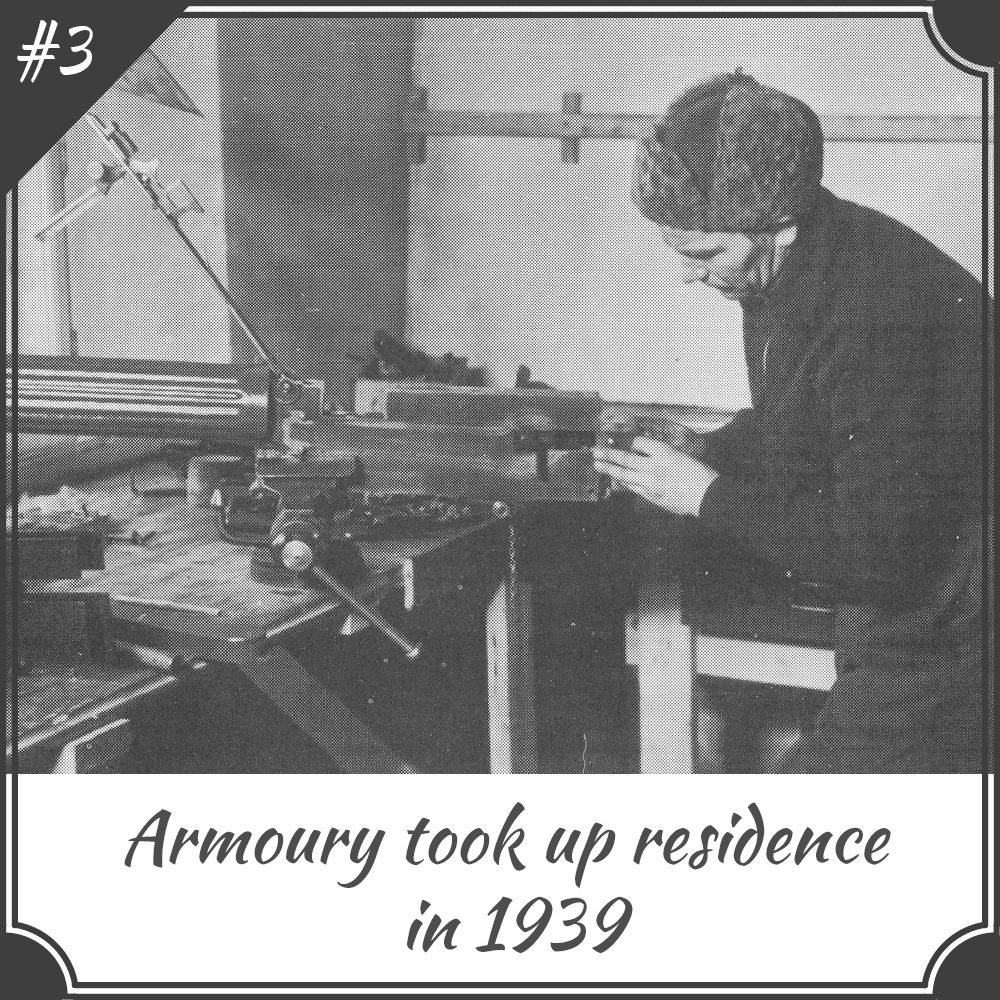

In the 1930s and 1940s the most important product for Vammalan Konepaja were pumps for domestic wells. There was much need for NIRA hand pumps after the Continuation War; farms were created in northern and eastern Finland for evacuees from Karjala, and these new farms needed water supplies. At the same time, Vammalan Konepaja concentrated on developing and manufacturing machines needed in home and agriculture. Niilo Ranni ran Vammalan Konepaja for over 30 years. He died in 1953, and his wife Anna Ranni stepped into the role of leading the company. A woman in a position of leadership in a company was very rare in the 1950s.

Part 5:

The company’s best-selling product, the pressure pump, and the aluminium bodied NIRA 6 pump began to be exported to other countries. In the late 1960s Vammalan Konepaja exhibited its products at trade fairs in Stockholm and Oslo. The NIRA pressure pump was a new kind of product on both the Swedish and Norwegian markets. Marketed as the ’Hyttepumppe’, the NIRA 6 pump sold particularly well in the mountainous regions of Norway in the years following the trade fair.

There has also been much demand for Vammalan Konepaja’s water pumps in Africa. With the help of development aid, the company developed a village water pump and started to export it to Africa, beginning with Tanzania in 1976. The company was introduced to the African market by a Ministry of Foreign Affairs development programme to provide wells. The NIRA AF-85 hand-operated pump was a test-winner in the World Bank's field and laboratory tests, a testimony to the company’s successful product development.

Part 6:

Vammalan Konepaja made the move to wellness and medical technology by accident in the beginning of the 1980s. Seppo Suuriniemi, CEO at that time, manufactured a treatment table for her wife’s physiotherapy office. The new treatment table became a success and Instrumentarium added it to their selection. Soon the treatment table reached international markets as well.

Konepaja became known within physiotherapy at the latest when the Swedish team started using Konepaja’s treatment and massage tables at the Calgary Olympics in 1988. The treatment tables might have had something to do with the fact that Sweden won four gold medals and two bronze medals in the competitions. But what’s even more important, Finland received four gold medals, two bronze medals, as well as one silver medal!

Part 7:

In the 1980s, Konepaja made large investments in electrical mechanics, CNC technology, robot welding and a powder coating line, which enabled the accelerating development of the company. Thanks to its own iron and aluminum foundry and investments in machinery, the company had the possibility to produce all healthcare devices by itself, right from square one.

Vammalan Konepaja wanted to be a trailblazer in the IT field as well, which meant large investments in the latest IT devices. A MikroMikko 1, which was one of the most modern computers of its time, was acquired in 1983. What might one be able to achieve these days with the computer, which was equipped with a 2 MHz processor and a 5 MB hard drive?

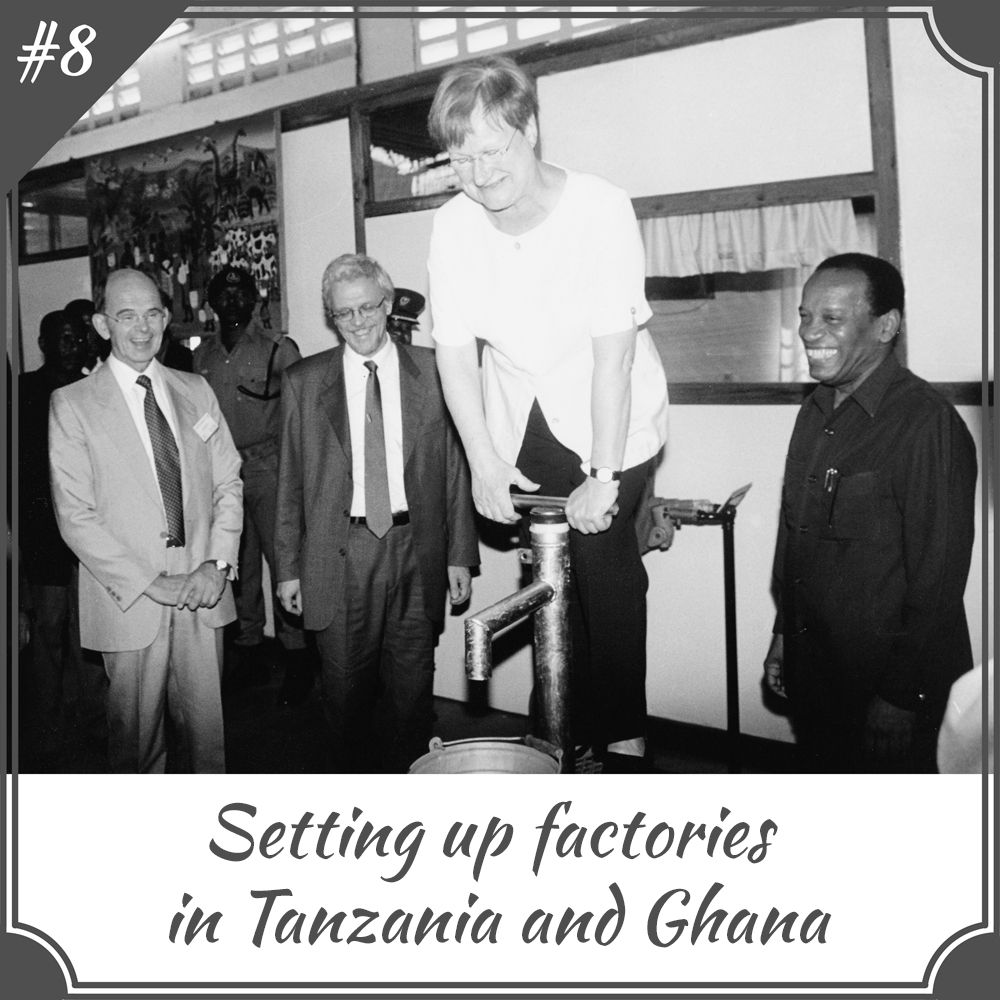

Part 8:

In the 1980s and 1990s well pumps were developed for African conditions and particularly for usage that was suitable for women. The pumps were lauded for being easy to use, easy to maintain and also for their durability. In 1991, as much as a quarter of the turnover of Vammalan Konepaja came from developing countries. Therefore, separate factories were set up in Tanzania and Ghana to manufacture the pumps. ⠀

⠀

The President, Tarja Halonen, visited the factory in Tanzania a few decades later in 2003 and was delighted by what she saw: "We're always thinking about how to get companies into the poorest countries; the really poor ones. Everyone knows that there's been no great rush into them. The pump factory of Vammalan Konepaja is a good example of a company that continued operating in Tanzania even after state support to them ended.”

Part 9:

Vammalan Konepaja bought hospital bed manufacturing and marketing rights from Lojer Oy in the 1980s. Between 1995 and 2004, the company expanded its operations through further acquisitions. In 2006, the company overhauled its brand, which is when the Lojer product name also became the company name. The Vammala Konepaja name no longer sent the message of a modern healthcare technology manufacturer.

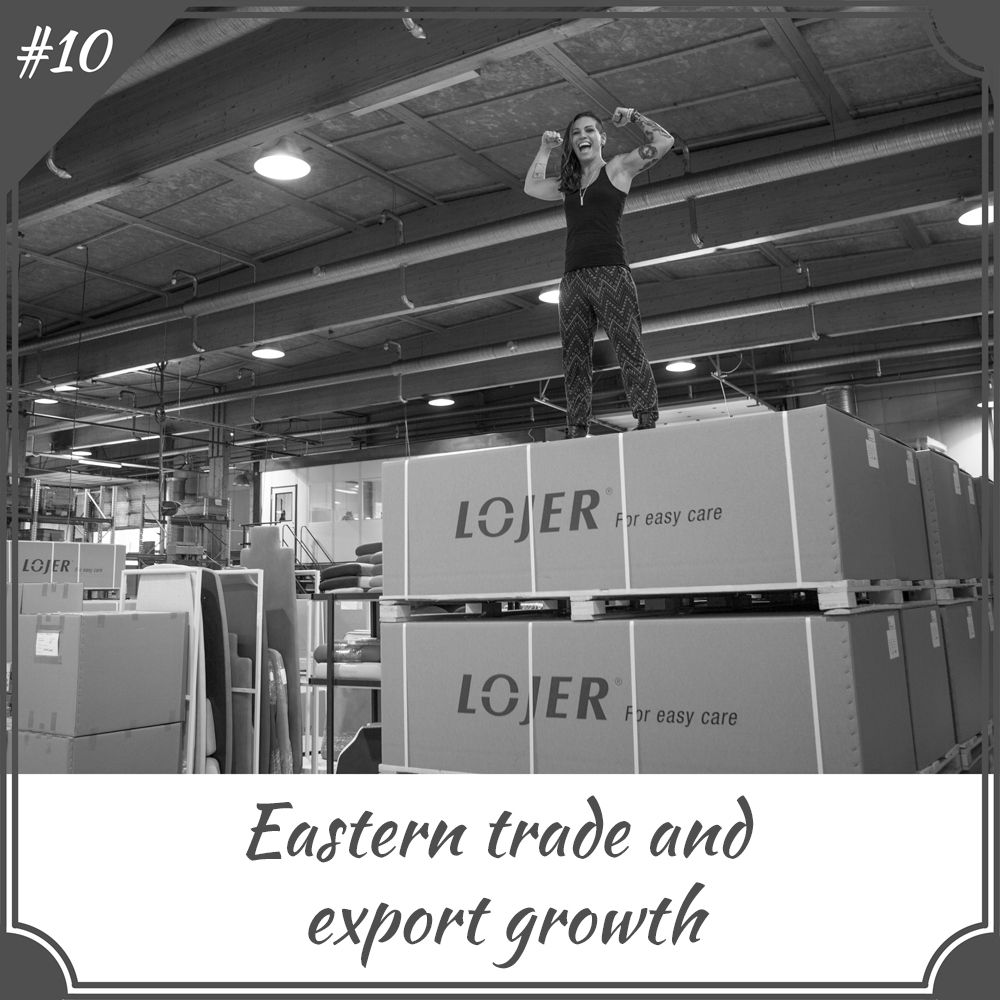

Part 10:

Lojer’s eastern trade took off after several slow years, when a company representation was established in Russia in 2009. At the same time, the product range was significantly adjusted to match the Russian market and needs. The sales target of 5 million was achieved in a mere two years instead of the estimated five!⠀

⠀

The high-quality Lojer products manufactured in Finland have since been a success throughout the world. The most distant export destinations include Chile, Saudi Arabia and South Korea. Lojer provided, for example, 70 operating tables and accessories to Indonesia in 2016. This was the largest single delivery in the history of Lojer, with a total value of approximately two million euros.

Part 11:

Lojer has always invested in product development. A good example of this is the Lojer Scandia operating table, which was released in 2008 and is equipped with state-of-the-art features. When it was released it was widely praised by professionals for its design, usability and technical features.⠀

⠀

The Manuthera 242 mobilization table has been called the most versatile treatment table in the world. Equipped with unique features and globally patented, this mobilization table has won several awards. In January 2017 Lojer received an award in the Fennia Prize competition for the Manuthera mobilization table's innovative product design and advanced technical engineering.

Part 12:

Since 2016 Lojer has been a member of the HygTech Alliance, an alliance of Finnish companies that is offering the world’s first complete range of hygienic products for resisting infections spread by touch. In creating its antimicrobial products Lojer has focussed on critical touch surfaces; on all these surfaces the traditional surface materials have been replaced with materials that actively stop the spread of bacteria. Also touch-free solutions – like a 2-piece adjustment bar - are added to some of the products.

Lojer supplied 80 antimicrobial examination tables to the new Meilahti children’s hospital in Helsinki, which was opened in 2018. The metal surfaces of the tables are painted with a special paint that resists the growth of microbes, the upholstery features silver ion treatment and the accessories feature antimicrobial copper or painted surfaces. The treatment tables have the lowest height adjustment on the market, making them ideal for the little patients at the children’s hospital.

Part 13:

Alongside its range of medical furniture and physiotherapy products, Lojer has also developed a comprehensive range of different services to compliment the product sales. 2018 Lojer acquired Teoteam Oy’s unit specialising in hospital equipment servicing.

Lojer launched its Functioning Care Facility service in 2013. In this concept the customer organisation does not own its beds, but instead leases them from Lojer. In addition to the beds themselves the customer receives all necessary mattresses, servicing and maintenance (including spare parts), and beds are exchanged when necessary. Leasing is also available for in-home care.

The law requires that healthcare organisations maintain a register of all healthcare equipment and accessories it uses. In 2017 Lojer launched the Lojer Easy Care equipment register, which allows healthcare organisations to maintain a real-time register of all their equipment.

Acute and

Acute and Delivery Unit

Delivery Unit Hospital

Hospital Nursing

Nursing Homecare

Homecare Outpatients

Outpatients Physio-

Physio- Surgery and

Surgery and Veterinary

Veterinary